Ballistic Dangers from Steel Fabrication

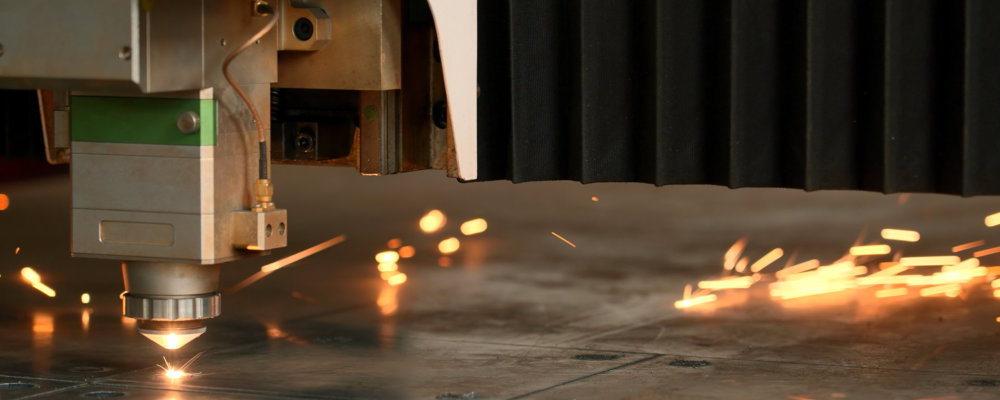

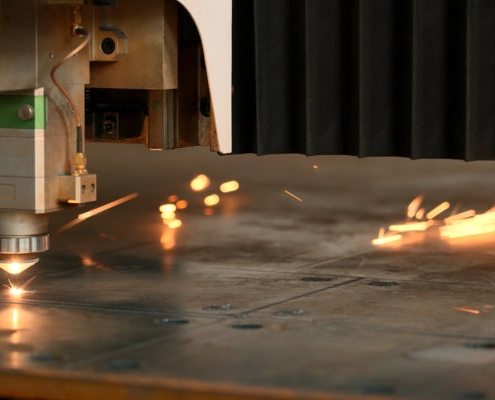

Improperly fabricated steel targets pose significant ballistic hazards because many common fabrication processes alter the steel’s hardness, microstructure, or surface condition.

Techniques such as laser cutting, plasma cutting, abrasive saw cutting and drilling can create heat-affected zones (HAZ) where the steel becomes softened or, in some cases, excessively hardened and brittle.

Research on HAZ behaviour shows that thermal cutting processes change hardness profiles and may introduce micro-cracks and uneven surfaces that promote unpredictable bullet fragmentation or ricochet (ASM International, Heat Affected Zone Characteristics; Welding Handbook, AWS).

Welding presents similar risks: the weld seam and surrounding HAZ experience significant microstructural change, reducing impact resistance and creating crater-prone areas (AWS D1.1). Studies on thermal cutting also show increased edge hardness and brittleness, which can cause bullets to splash or deflect erratically (NIST, Thermal Cutting Effects on Steel Properties).

- ASM International. Metals Handbook – Heat Affected Zone Characteristics in Steel. ASM Handbook Vol. 6: Welding, Brazing, and Soldering.

- American Welding Society (AWS). Welding Handbook and AWS D1.1 Structural Welding Code – Steel (HAZ softening and hardening effects).

- National Institute of Standards and Technology (NIST). Effects of Thermal Cutting Processes on Steel Microstructure and Hardness.

- Kou, Sindo. Welding Metallurgy. Wiley. (Microstructural transformations in thermal cutting and welding).

You may also be interested in

https://www.ballistex.com.au/wp-content/uploads/2026/01/Anything-can-cause-ricochet-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:20:252026-01-06 23:01:37Anything Can Cause Ricochet: Understanding Ballistic Behaviour Across Materials

https://www.ballistex.com.au/wp-content/uploads/2026/01/Anything-can-cause-ricochet-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:20:252026-01-06 23:01:37Anything Can Cause Ricochet: Understanding Ballistic Behaviour Across Materials https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistic-Dangers-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:18:202026-01-06 23:03:13Ballistic Dangers from Steel Fabrication

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistic-Dangers-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:18:202026-01-06 23:03:13Ballistic Dangers from Steel Fabrication https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistic-Testing-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:16:142026-01-06 23:04:35Ballistic Testing versus Shooting and Hoping

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistic-Testing-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:16:142026-01-06 23:04:35Ballistic Testing versus Shooting and Hoping https://www.ballistex.com.au/wp-content/uploads/2026/01/Bending-Bullets-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:11:542026-01-06 23:09:56Bending Bullets

https://www.ballistex.com.au/wp-content/uploads/2026/01/Bending-Bullets-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:11:542026-01-06 23:09:56Bending Bullets https://www.ballistex.com.au/wp-content/uploads/2026/01/Advantages-of-Engineered-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:05:542026-01-06 23:06:19Advantages of Engineered Targets and Range Systems

https://www.ballistex.com.au/wp-content/uploads/2026/01/Advantages-of-Engineered-2.jpg

400

600

admin

https://www.ballistex.com.au/wp-content/uploads/2026/01/Ballistex-Logo.png

admin2026-01-04 22:05:542026-01-06 23:06:19Advantages of Engineered Targets and Range Systems